IGS North America Presents:

IGS North America Presents:

Electrical Leak Location Webinar Series

The Dipole Method (ASTM D7007): Advantages, Technique, and Necessary Site Conditions

Presented by Abigail Gilson, M.S., P.E.

Date: Tuesday, April 24, 2018 @ 1:00 – 2:30pm EDT (includes Q&A time)

Registration Cost:

$20.00* – IGS-NA Members | $80.00 – Non-members

* IGS-NA Members receive one FREE webinar coupon on paying annual dues

EARN 1 PDH

Presenter: Abigail Gilson, Director of TRI Environmental’s Liner Integrity Services

ABeck@TRI-ENV.com | +1 512 623 0511

The Dipole Method (ASTM D7007): Advantages, Technique, and Necessary Site Conditions

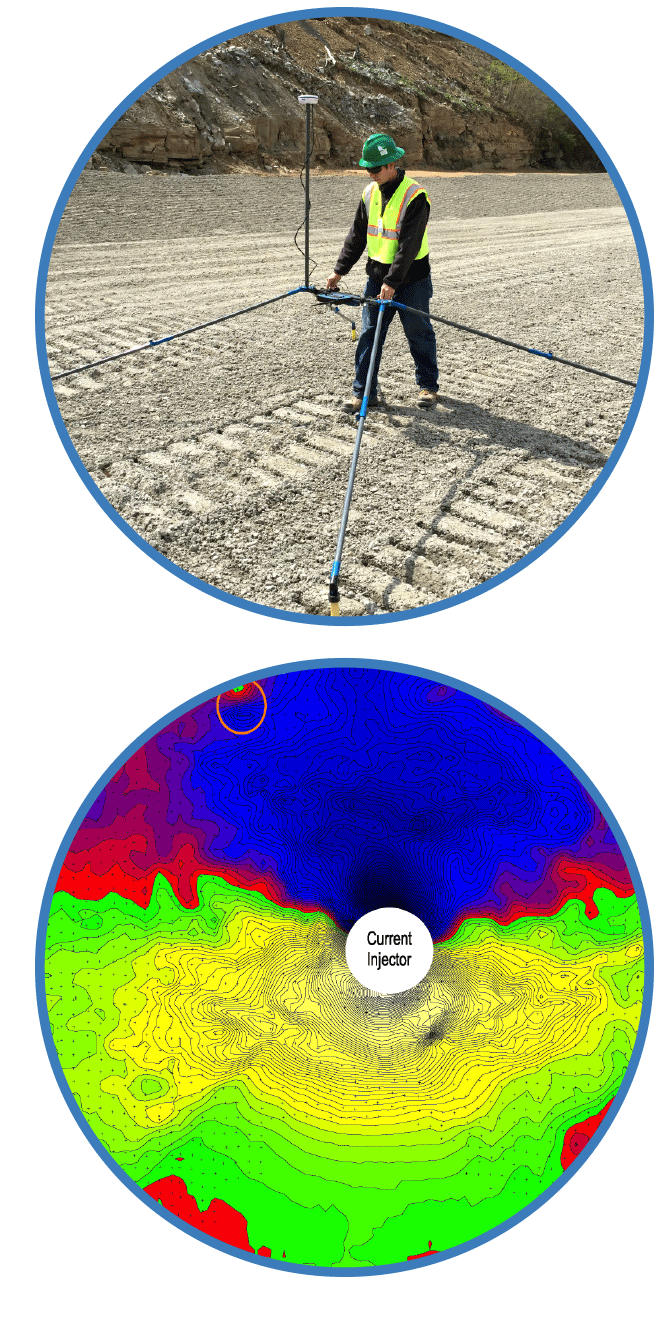

Among the various types of electrical leak location methodologies used to evaluate geosynthetic lining systems in the field, the dipole method has a unique distinction: it is the only ASTM standardized ELL practice that can locate damage to geomembranes caused during or after cover material placement. Dipole technology can locate very small damage points, such as pinholes or knife slices, under several feet of earthen material. It can even be applied to filled impoundments that are actively in service. As such, dipole surveys are a powerful tool for lined facility validation and protection; but, like any ELL methodology, it can be rendered ineffective if site boundary conditions are poor. In this webinar, Abigail Gilson-Beck, one of the leading experts on ELL, explains ASTM D7007 standardized procedures, including leak detection distance testing and the various methods of data analysis. The importance of good site boundary conditions is detailed with case studies. Earn 1 PDH at the conclusion of the first webinar.

DOWNLOAD EVENT PDFAttendees will learn about:

The Electrical Leak Location Series is ideal for design engineers, CQA firms, site owners, and regulators interested in specifying and employing this service.

Presenter Bio: Abigail Gilson, M.S., P.E., is the Director of TRI Environmental’s Liner Integrity Services. She has a wealth of experience in geomembrane-lined containment facility design and construction and has performed electrical leak location surveys since 2004. As a graduate of TRI’s inaugural liner integrity class in 2003, her electrical leak location field experience has exceeded 100 projects and 110 million square feet. She has written and presented papers to industry conferences and taught short courses worldwide regarding the technical aspects of liner integrity and leak location surveys.

Presenter Bio: Abigail Gilson, M.S., P.E., is the Director of TRI Environmental’s Liner Integrity Services. She has a wealth of experience in geomembrane-lined containment facility design and construction and has performed electrical leak location surveys since 2004. As a graduate of TRI’s inaugural liner integrity class in 2003, her electrical leak location field experience has exceeded 100 projects and 110 million square feet. She has written and presented papers to industry conferences and taught short courses worldwide regarding the technical aspects of liner integrity and leak location surveys.

Ms. Gilson’s expertise is available for providing equipment, field training, classroom education, instructional presentations, engineering consulting, and liner integrity survey execution. She has trained staff in all of TRI’s office locations to provide local assistance on survey projects.