The Young Professionals Program at GeoAmericas 2016 has announced its GeoPrediction Competition. This team-based event will focus on predicting the face displacement of an MSE wall constructed with poorly draining backfill. The objective of the GeoPrediction Competition is to develop an accurate prediction of the behavior of a geotechnical system involving geosynthetics, given detailed information regarding subsurface, boundary, and initial conditions, as well as the geotechnical, structural, and hydraulic loading.

The Young Professionals Program at GeoAmericas 2016 has announced its GeoPrediction Competition. This team-based event will focus on predicting the face displacement of an MSE wall constructed with poorly draining backfill. The objective of the GeoPrediction Competition is to develop an accurate prediction of the behavior of a geotechnical system involving geosynthetics, given detailed information regarding subsurface, boundary, and initial conditions, as well as the geotechnical, structural, and hydraulic loading.

The use of any available geotechnical software and empirical correlations is allowed, as is the development of a simple, accurate computer code for making this prediction.

Questions are welcomed. Email GeoAmericas2016youngmembers@gmail.com.

Eligibility, deadline, and the MSE problem description follows.

Eligibility: A Geosynthetics Prediction Team will consist of one or two younger members. There is no limit on the number of teams from a given institution or company.

Eligibility: A Geosynthetics Prediction Team will consist of one or two younger members. There is no limit on the number of teams from a given institution or company.

Submittal: Each Geosynthetics Prediction Team will submit a Geosynthetics Prediction Report containing, a minimum, the following information:

Judging: The submitted Geosynthetics Prediction reports will be judged and ranked by a panel of geotechnical engineers. The judging will be based on the criteria listed below.

Announcement: The top three reports will be ranked by the panel and will be presented with awards during the IGS awards ceremony at GeoAmericas 2016.

Questions: Send any questions to GeoAmericas2016youngmembers@gmail.com.

PROBLEM DESCRIPTION & AVAILABLE DATA

PROBLEM DESCRIPTION & AVAILABLE DATA

A geotextile-reinforced prototype mechanically-stabilized earth (MSE) wall was constructed using wrap-around facing with a width of 4m, a height of 4m and a length of 4m. The wall was built with 10 geotextile layers evenly spaced at 0.40m vertically. The reinforcement length was equal to 3.0m. The MSE wall was constructed atop a firm foundation that can be assumed to be rigid with first geotextile layer placed at the ground level. In the design, the reduction factors against creep, durability and installation damage were taken as 1.0. The wrap-around system was assembled using metallic supports and wood boards, for a final angle of 78o from horizontal, resulting in a face slope of 5V:1H. The geotextile material used in the wall was a short-fiber needle-punched polyester non-woven geotextile with the following characteristics:

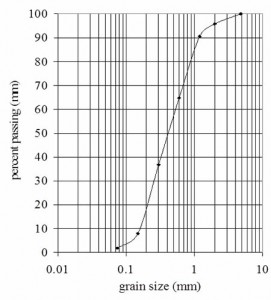

Backfill soil consisted of a fine to medium well-graded sand which was compacted using a vibratory plate hammer. The grain size distribution of backfill soil is presented in Figure 1. The maximum and minimum void ratios, emax and emin were 0.70 and 0.46. The backfill soil was compacted to a target relative density of 80% which corresponds to a void ratio of 0.51 and dry unit weight of 17.7 kN/m3. The backfill was placed in the field at a gravimetric water content of 5.0%. The soil has a drained friction angle of 33°.

Goal

Estimate the deflections of the wall face as a function of wall height due to the wall’s self-weight immediately after construction.

**

VISIT THE GEOAMERICAS 2016 WEBSITE for more information on the Young Professionals Program, the International Geosynthetics Society (IGS), short courses, and much more.